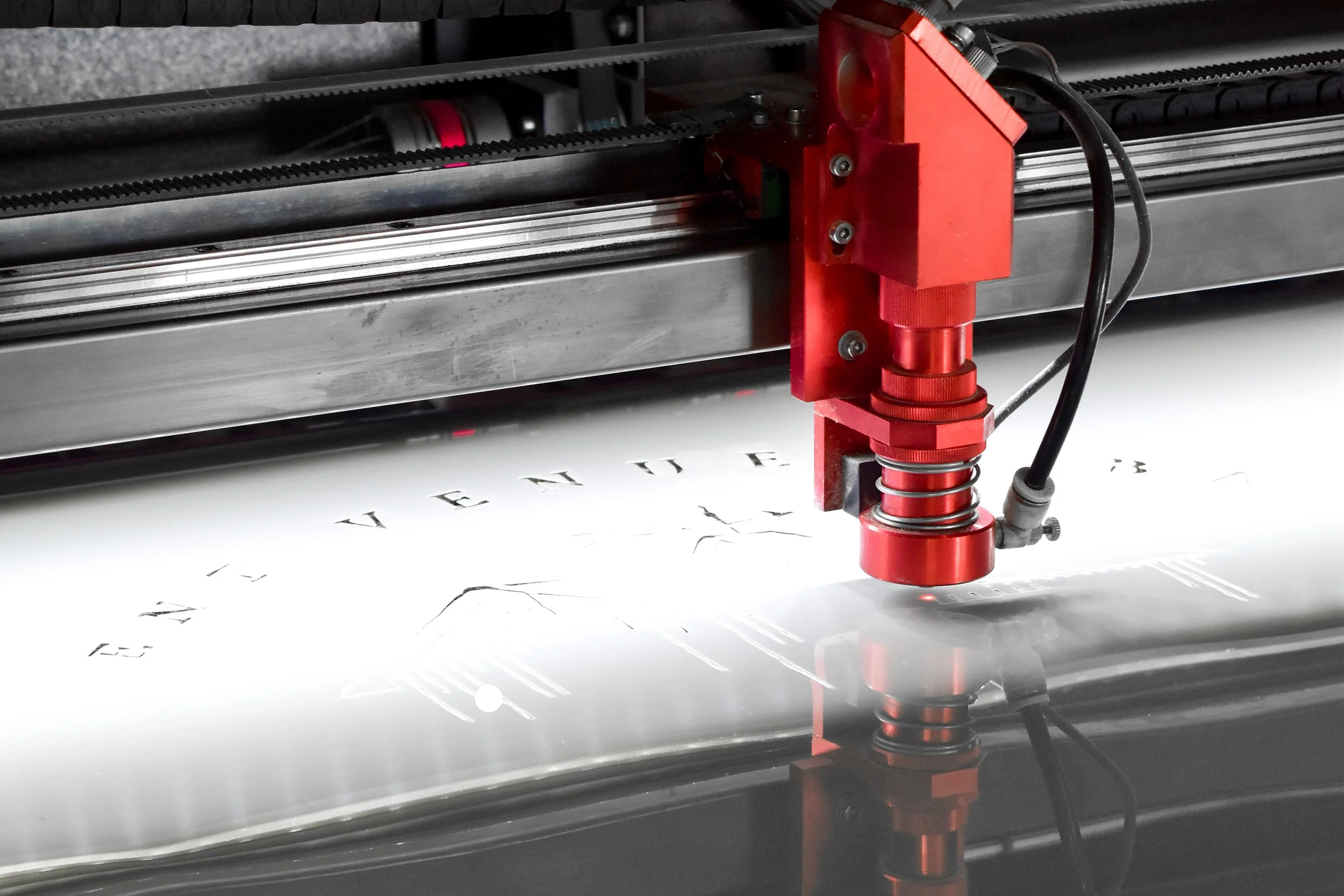

LASERCUT & STAMP

Metal stamping converts flat metal sheets into specific shapes, which could be blanking, punching, and bending. Usually, stamping punches features out of sheet metal using reinforced steel toolings, and laser-cut does the same thing using CNC programming, but without toolings involved.

Progressive toolings are tooling that incorporates more than two different stamping toolings simultaneously. They may combine feature numbers of stamps and flips, which can make a complex geometry to meet faster production time but will result in high tooling costs.

Metal Trimming is the sample, using toolings to deburr any flashes that occurred during a die-casting process. Using this method, the bigger metal flash, can quickly and precisely be removed instead of manually removing it by hand and sandblasting.

Metal stamping transforms raw metal sheets into finished components with the following processes:

Bending

Embossing

Notching

Punching

Stamping

Tooling

While increasingly advanced metal stamping tools can create high-quality parts, selecting the appropriate raw materials is just as important as choosing the proper machining process. Each metal and alloy has different characteristics. Depending on the nature and application of the part, it might need either a standard alloy or a specialty metal.

Many common alloys are used as precision metal stamping materials across multiples industries, such as:

Aluminum alloys

Brass alloys

Copper alloys

Nickel alloys

Steel and stainless steel

It’s essential for designers and engineers to know critical information about the most common metals and specialty metals available for metal stamping processes to inform the material selection process.